30KhGSA is a(n) Russian steel defined in GOST8733-87 standard.

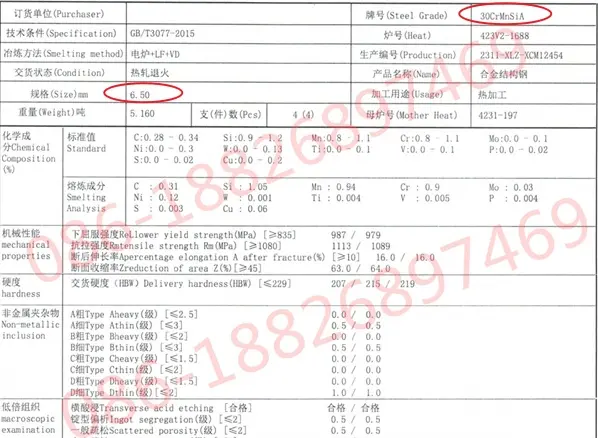

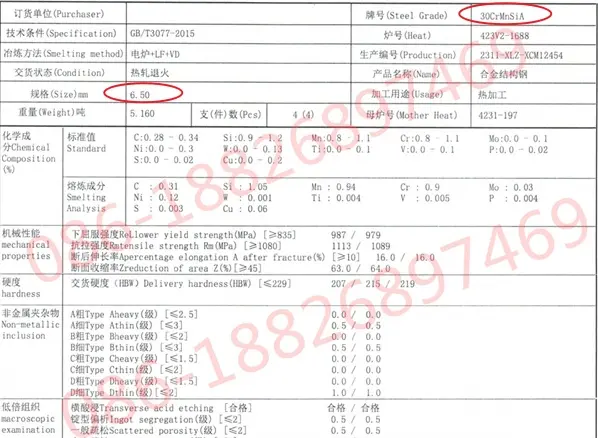

30CrMnSiA is a(n) Chinese steel defined in GB/T 3077 standard.

30HGSA /30ChGSA /35HGS /30KhGSA /30CrMnSiA /30ХГСА structural alloy steel for thermal improvement, heavy-duty constructions and construction of parts of heavy-duty machines - aviation steel according to PN-89/H-84030/04.

Products: Strip profile and hot-rolled plate products, forgings, pipes, wire rod and long products, including shaped.

The main element of this steel product is iron, accounting for 96%. The presence of chromium (0.8−1.1%) in the composition imparts corrosion resistance to the alloy, and thanks to manganese (0.8−1.1%), the wear and impact resistance of the metal is increased.

At the same time, the 0.9% to 1.2% silicon content increases toughness and ductility, allowing you to use stamping and forging to process steel.

| Steel Grade | Standard | C | Mn | Si | P | S | Cu | Cr | Ni | Mo | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

30ChGSA |

GOST | 0.25~0.34 | 0.80~1.10 | 0.90~1.20 | max 0.025 | max 0.025 | max 0.30 | 0.80~1.10 | max 0.30 | - | - |

|

30CrMnSiA |

GB/T YB/T |

0.28~0.34 | 0.80~1.10 | 0.90~1.20 | max 0.025 | max 0.025 | max 0.30 | 0.80~1.10 | max 0.30 | - | - |

|

30HGSA |

PN | 0.28~0.34 | 0.80~1.10 | 0.90~1.20 | max 0.025 | max 0.025 | max 0.30 | 0.80~1.10 | max 0.30 | - | - |

|

30HGS |

PN | 0.28~0.35 | 0.80~1.10 | 0.90~1.20 | max 0.035 | max 0.035 | max 0.30 | 0.80~1.10 | max 0.30 | - | - |

|

35HGSA |

PN | 0.32~0.39 | 0.80~1.10 | 1.10~1.40 | max 0.03 | max 0.025 | max 0.30 | 1.10~1.40 | max 0.30 | - | - |

|

35HGS |

PN | 0.32~0.39 | 0.80~1.10 | 1.10~1.40 | max 0.035 | max 0.035 | max 0.30 | 1.10~1.40 | max 0.30 | - | - |

|

30ChGSA |

BDS | 0.28~0.34 | 0.80~1.10 | 0.90~1.20 | max 0.025 | max 0.025 | max 0.30 | 0.80~1.10 | max 0.30 | max 0.15 | - |

|

30ChGSA-PV |

TU14-1-5419-2001 | 0.28~0.34 | 0.80~1.10 | 0.90~1.20 | max 0.025 | max 0.025 | max 0.30 | 0.80~1.10 | max 0.30 | max 0.15 | V max 0.05 Ti max 0.03 W max 0.20 N max 0.008 |

| Standard | Yield strength, N/mm2 | Temporal resistance, N/mm2 | Relative elongation % | Relative reduction % |

|---|---|---|---|---|

|

DSTU 7806 / GOST 4543 |

835 | 1080 | 10 | 45 |

Grade 30HGSA /30ChGSA /35HGS /30KhGSA /30CrMnSiA /30ХГСА is used to build high-strength parts for heavy and medium machines, such as: journals, shafts, arbors, axles, gears, rollers, rings, clutch parts, sleeves, levers, covering by Body, flanges, compressor blades pressed from sheet metal, working under heavy loads at temperatures up to 150-200°C, and riveted structures, also welded and then heat-treated for small cross-sections, pipes This grade of material is also Made seamless for use in the aerospace field, for various structural elements.

For small and medium sections, it can replace chromium-molybdenum steel and chromium-nickel steel. When used in quenched and quenched and tempered conditions, 30HGS steel has significant hardenability, allowing it to achieve the best mechanical properties at a thickness of about 60mm after oil quenching. Steel is prone to temper brittleness and has limited weldability, especially in thicker sections.

30HGSA /30ChGSA /35HGS /30KhGSA /30CrMnSiA /30ХГСА steel is suitable for joining by electric, resistance or friction welding methods. The optimal parameter range for resistance welding is narrower than for welding mild steel. Metallurgical products made of this steel grade can be welded in the heat treated or softened annealed state. When welded and properly heat treated, the mechanical properties of the weld will be similar to those of the material being welded.

The recommended welding methods are manual arc welding, argon arc welding, submerged arc welding and shielded welding.

30HGSA /30ChGSA /35HGS /30KhGSA /30CrMnSiA /30ХГСА steel can be gas cut using oxygen acetylene or propane butane oxygen flames, or arc cut using plasma flow. The steel should be preheated to 200-250 °C for cutting. The cutting surface should be cooled in calm air.

In 30HGSA or equivalent grade (30KHGSA, 30HGSA-PV / 30HGSA-PW), we supply seamless cold drawn tube, round rolled bar, drawn bar H11, H9 free forging, round bar, square bar, hexagonal bar, Flat bars, plates, cubes, hot-rolled seamless pipes, hot-rolled and cold-rolled plates.

Customized Processing Specifications